Lubing Switches: Where to Lube

This short will be an absolute first for the website as it was not written nor edited by me. Originally constructed by Awalkerstop, or otherwise known as Walker of ‘Walker’s Keyboard Science’, this document was originally published on September 18th, 2018 onto Imgur. However, announcements from Imgur in early 2023 are hinting at a removal of nearly all NSFW content from their platform as of May 15th of 2023 and rumors are swirling that older content beyond a few years old may be scrubbed too. I simply could not risk losing this piece of history as it is by far one of the best standalone pieces of switch science I have ever come across in this hobby. So, I’ve constructed it here word for word as it was originally published in the event it does get removed.

If the original is still around, you should go read it here first.

One goal of lubing switches is to reduce friction. We can figure out which parts of the switch need lube by checking where there's friction, where the stem is rubbing against the housing.

The subject for this study is a Gateron milky linear switch with a white stem. This is a great switch for this injestigation because both the stem and the housing are white.

Here is the stem of the switch. To begin, I have thoroughly cleaned both the stem and the housing with isopropyl alcohol, Q-tips, and microfiber cloth.

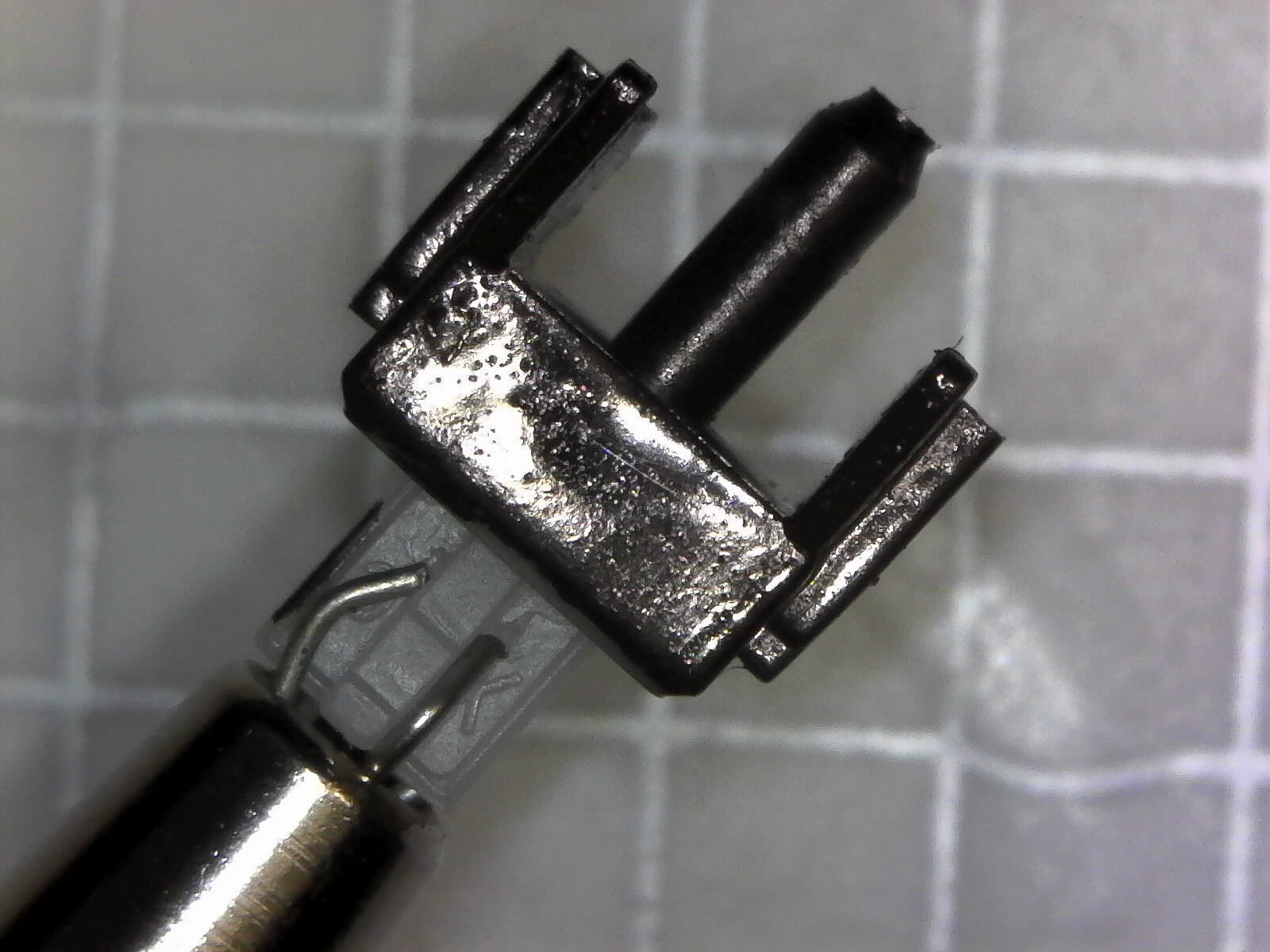

Next, I used a black felt-tipped marker to color every part of the stem that I think could possibly rub against the switch housing.

Another view of the "painted" stem. The marker leaves a somewhat thick coat that I hope will rub off in areas where the stem rubs against the housing, leaving a mark on the housing and showing us what areas we should lube. Conversely, if the marker doesn't rub off onto the housing, that means the stem didn't rub against the housing, so there's no need for lube there.

Another angle showing the "painted" stem.

Next I put the switch into my switch tester and put a keycap on it. I then pressed the key approximately 200 times straight on, then 100 times on the edge of each of the 4 sides of the keycaps, and 100 times on each of the 4 corners of the keycaps. I then pressed the switch at random directions a couple hundred more times, for good measure. The goal here is to try and simulate any possible keypress that the switch could undergo when used in a keyboard.

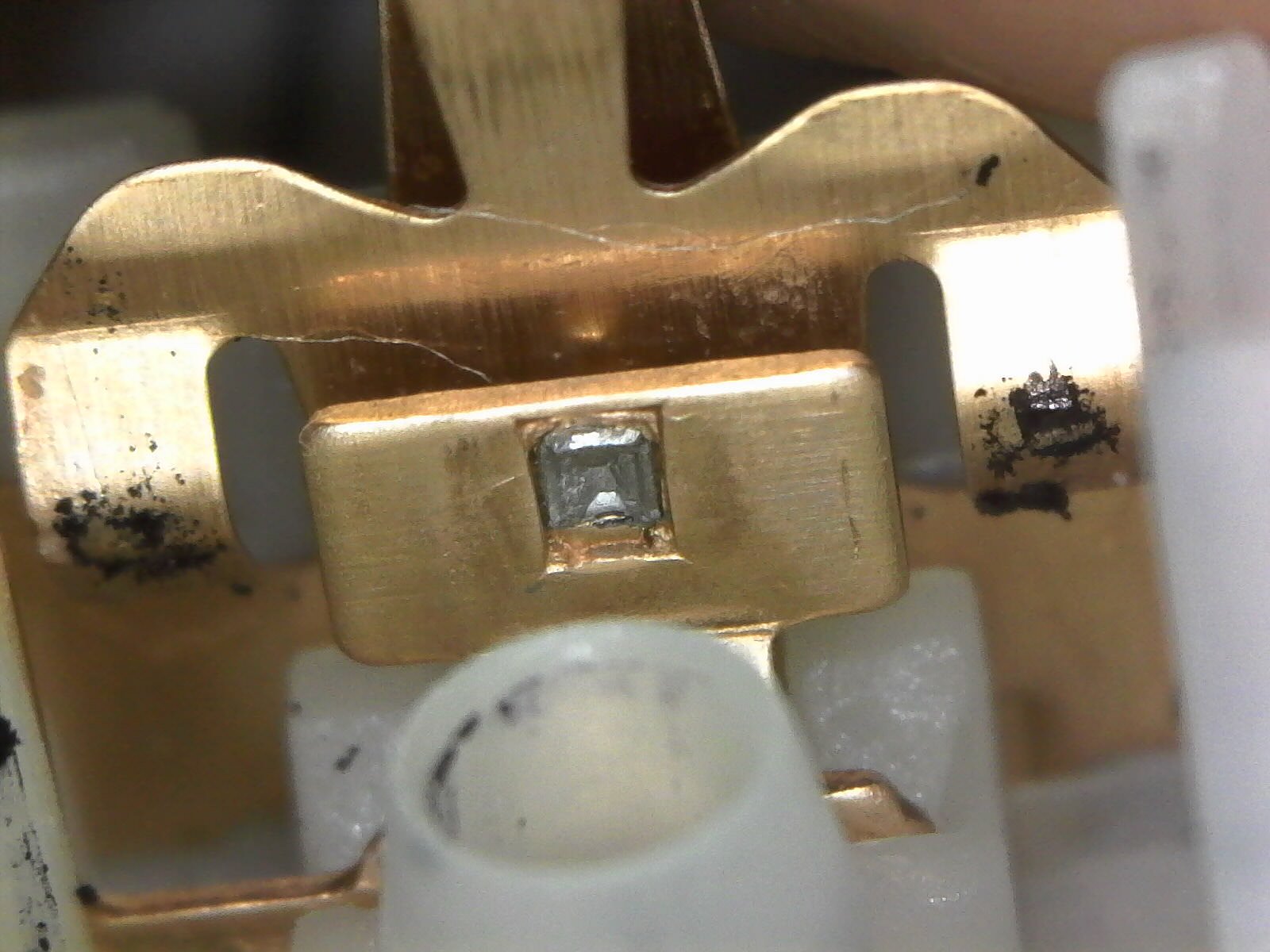

Now I have opened the switch up to look for where the marker rubbed off from the stem onto the housing. The first and maybe most obvious place is on the bumps of the leaf. Of course, the stem has to rub against this part in order for the switch to actuate. Lubing this part of the leaf can make the switch feel smoother and less "scratchy", and I would always do so on linear switches. For tactile switches, it's a little more complicated; lubing this part of the leaf will slightly decrease how tactile the switch feels. For a mildly-tactile switch like Cherry brown or Aliaz, lubing this part with a thick lube could make the switch almost feel like a linear. If you are trying to maximize tactility, you can either skip lubing this point, or you can use a thinner oil here which will have less impact on the tactility. If it's a linear switch or a switch that already has an intense tactility, such as Zealios, Cherry clear, etc., I feel like it's worth lubing this spot; you lose a bit of tactility but the switch feels smoother, and still tactile enough for my taste.

Another view of the stained leaf. Once again, always lube this spot for linears, but for tactiles consider the trade-off between tactility and smoothness. I would experiment on a few switches to help you decide whether you like the feeling of applying lube here for your tactile switches.

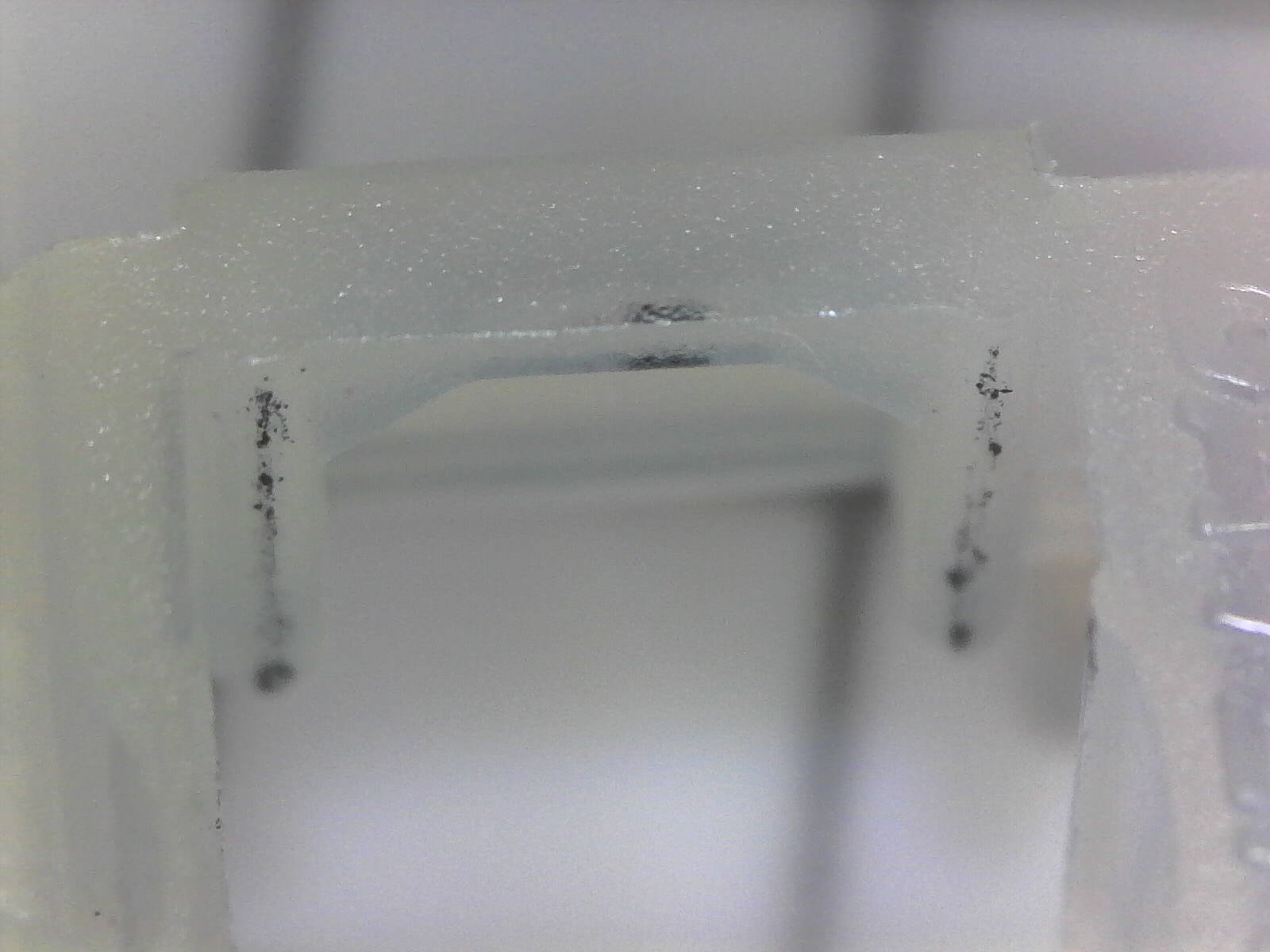

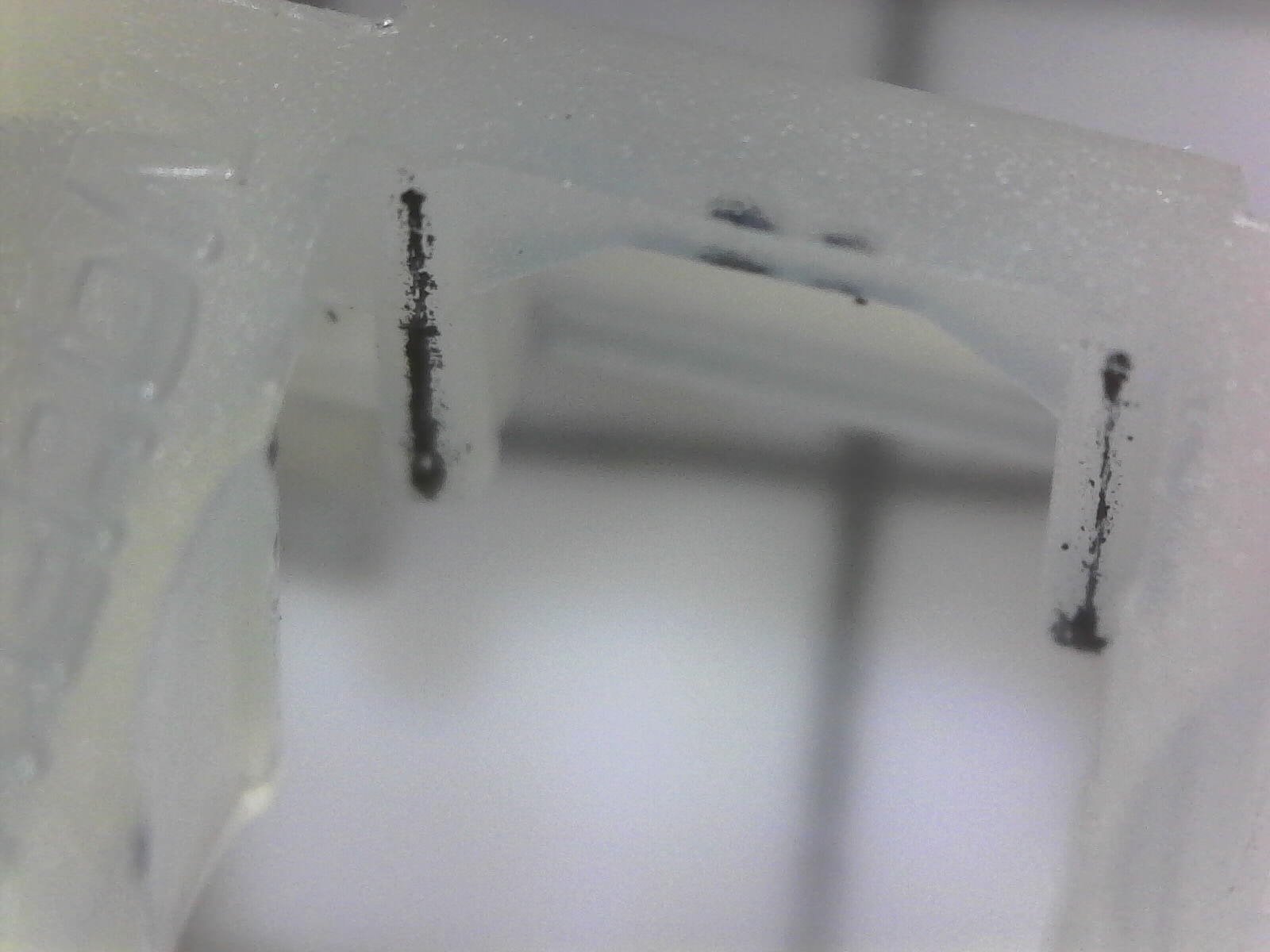

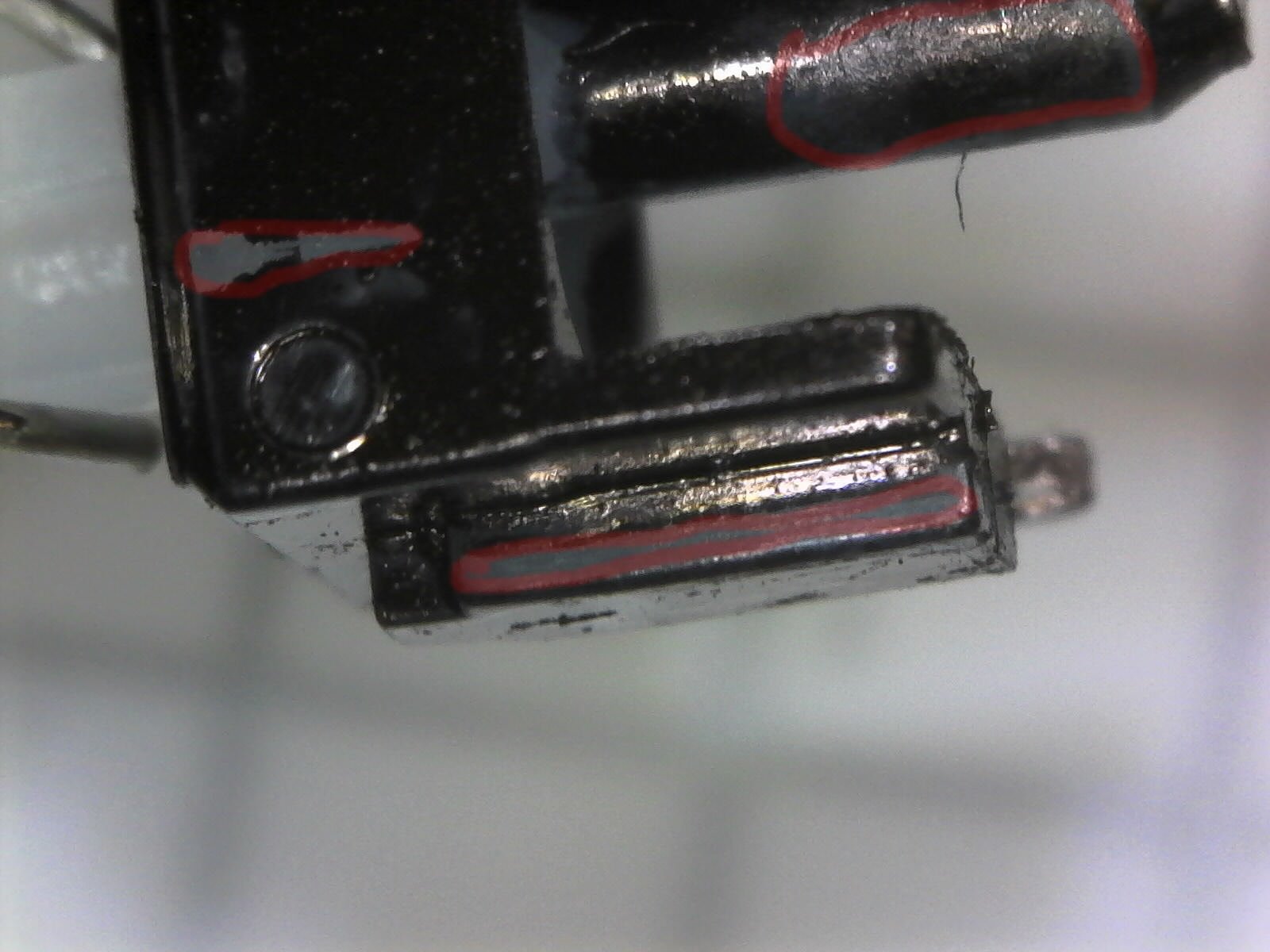

Next, I check the rails of the housing. Not surprisingly, the stem also rubbed against this spot, so ideally you'd want lube here, whether applied directly or transferred from the stem to the housing. If you don't apply lube to the housing parts in these areas of friction, you are relying on the stem carrying enough lube to "smear" it onto the entire sliding surface of the housing, which could be less reliable. A safer approach would probably be to lube both the housing and the slider.

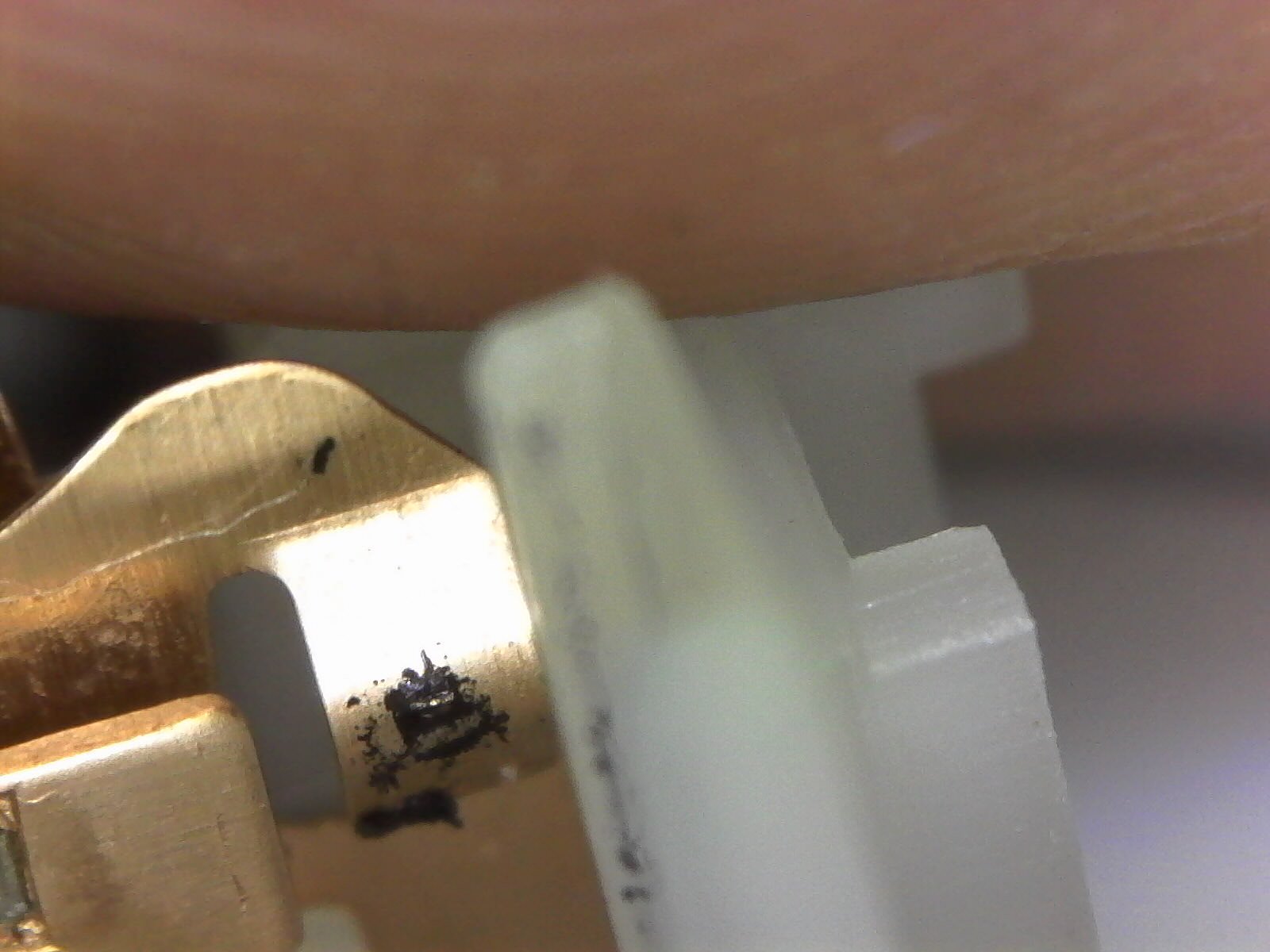

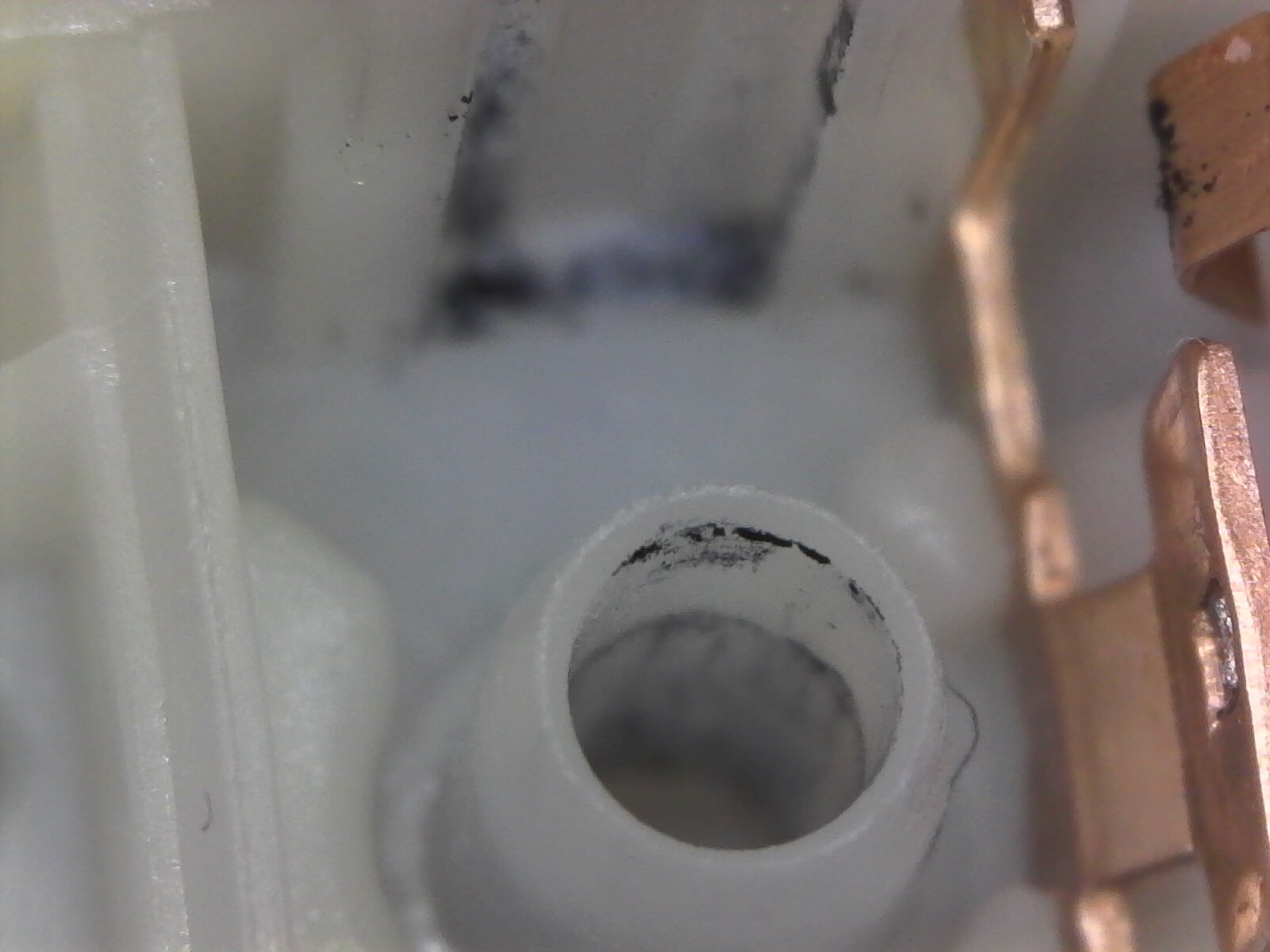

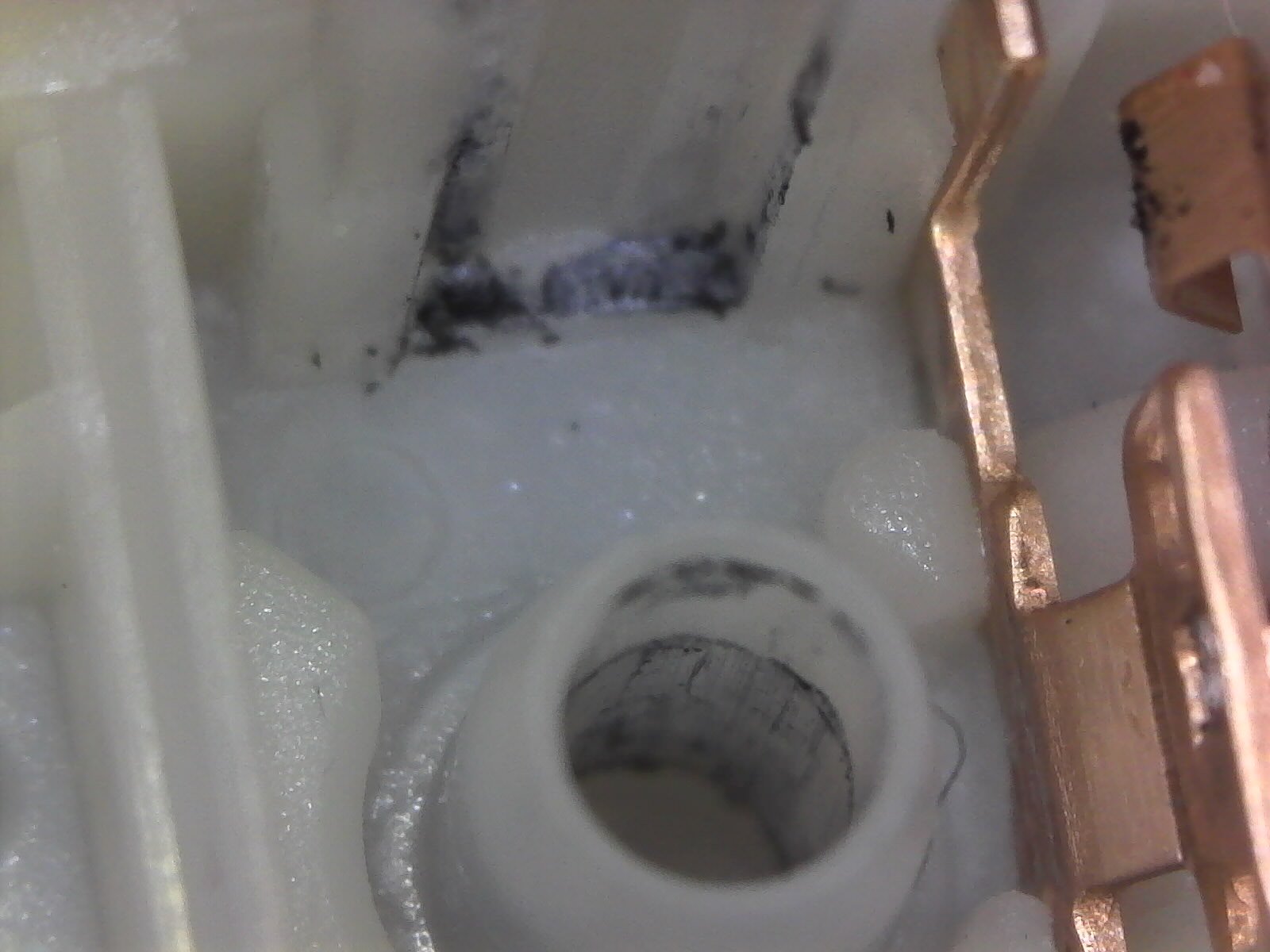

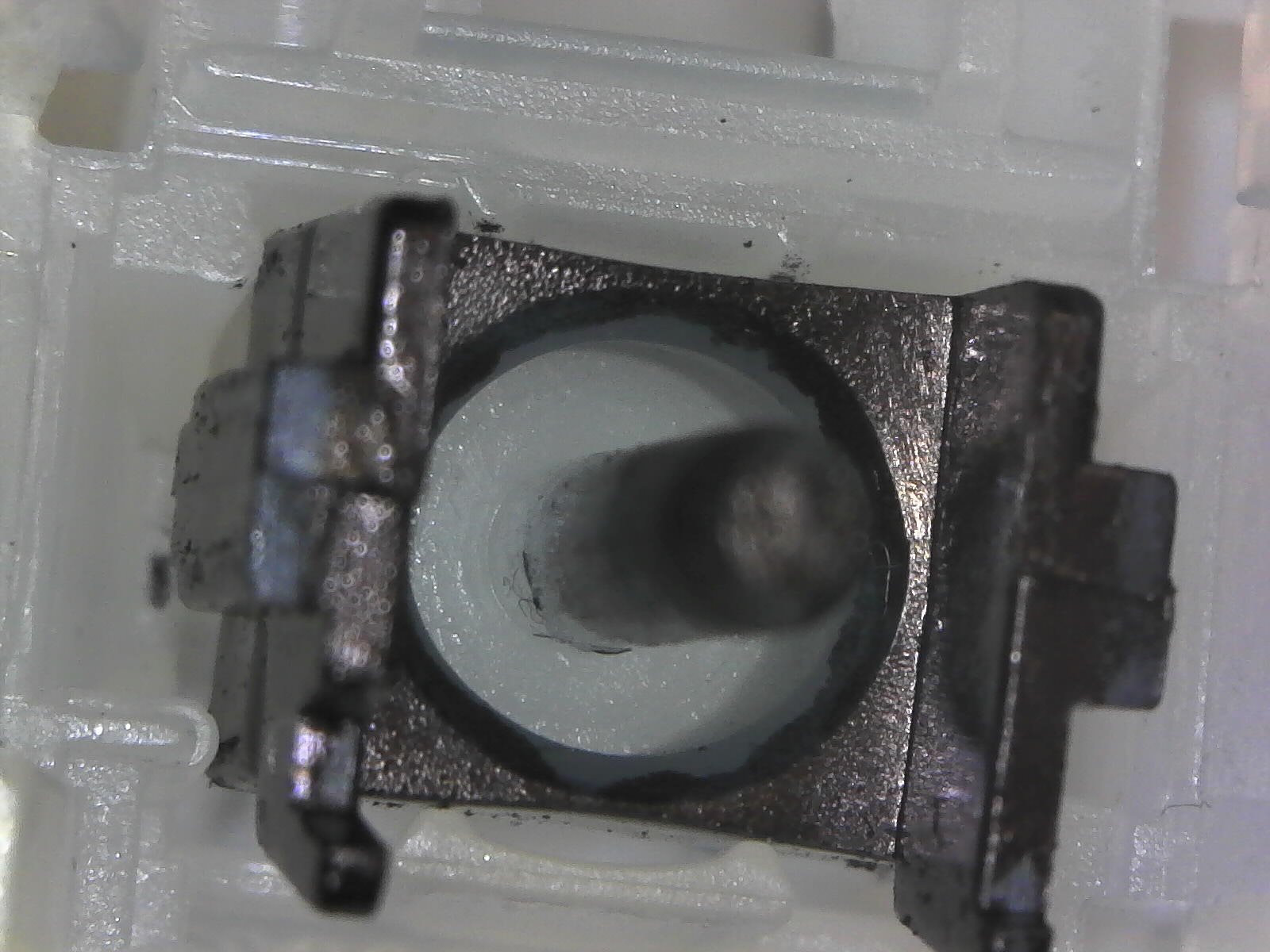

In this shot you can see that the stem rubbed against both the rails and the inside of the center tube of the spring guide. This suggests that you should lube the rails and inside of the spring guide tube, or lube all parts of the stem including the center post, or all of the above.

Another shot showing the friction of the stem center post against the inside of the spring guide tube

Another shot showing the friction of the stem center post against the inside of the spring guide tube

Another shot showing the friction of the stem center post against the inside of the spring guide tube

Another shot showing the friction of the stem center post against the inside of the spring guide tube

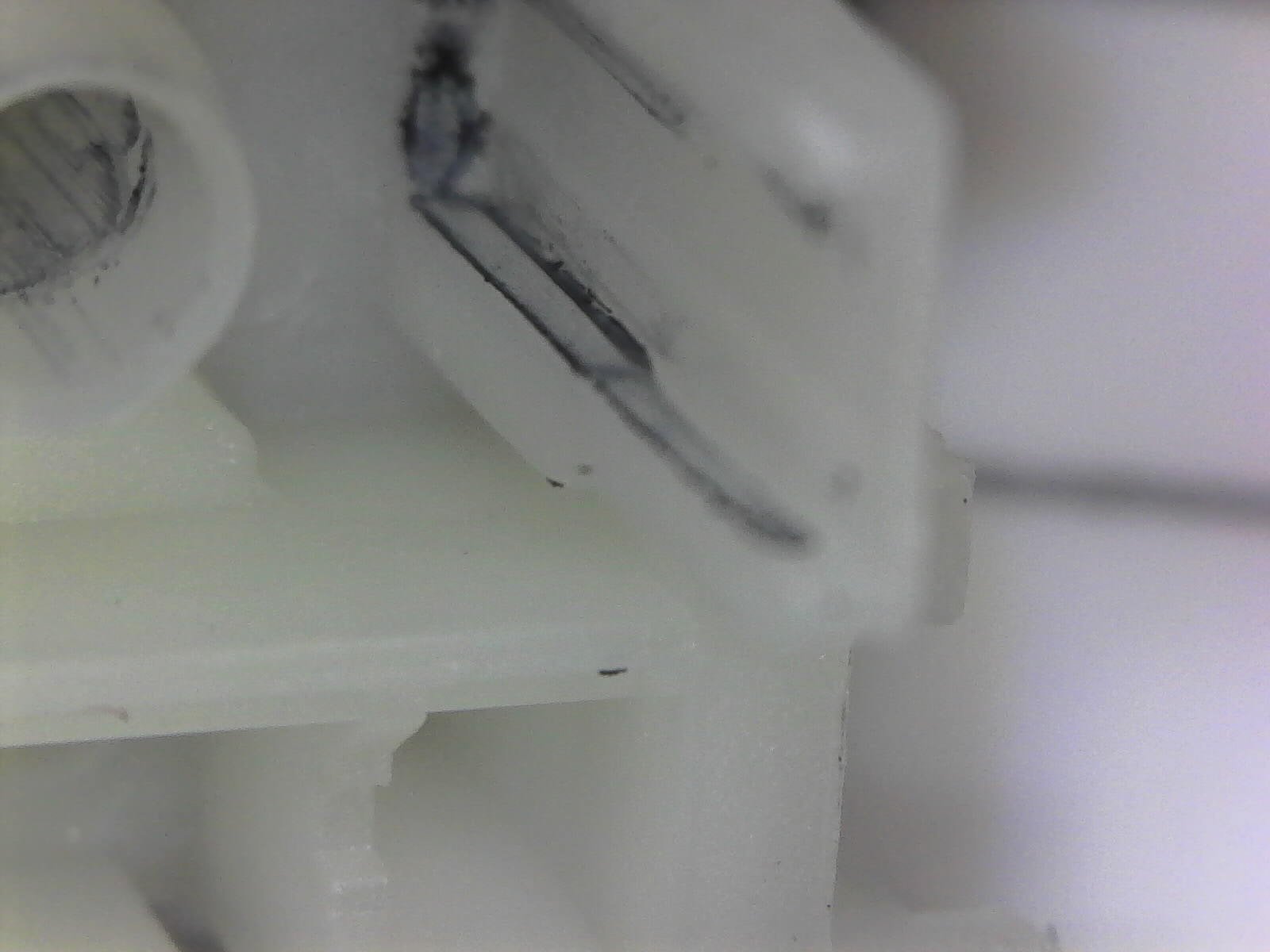

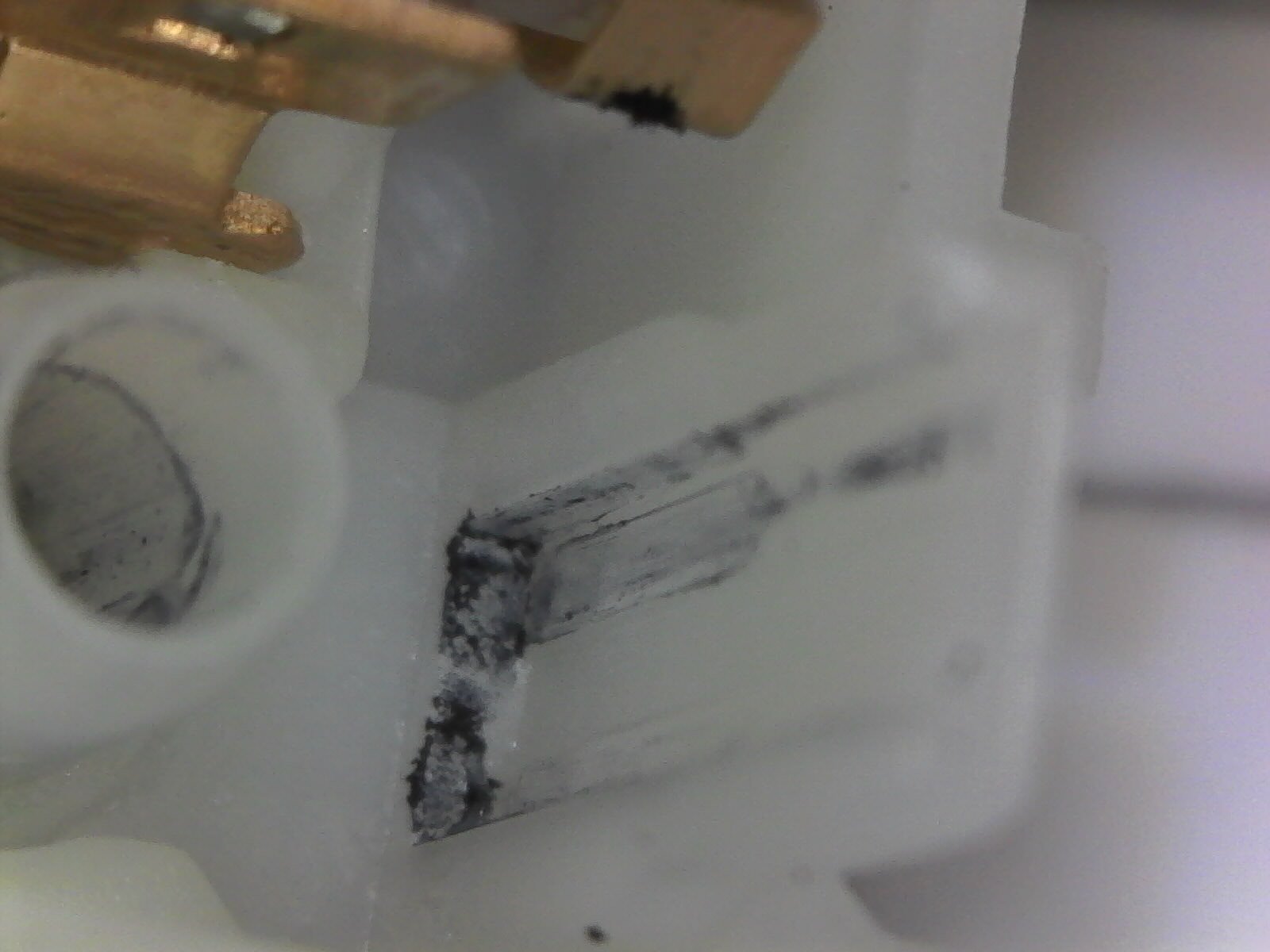

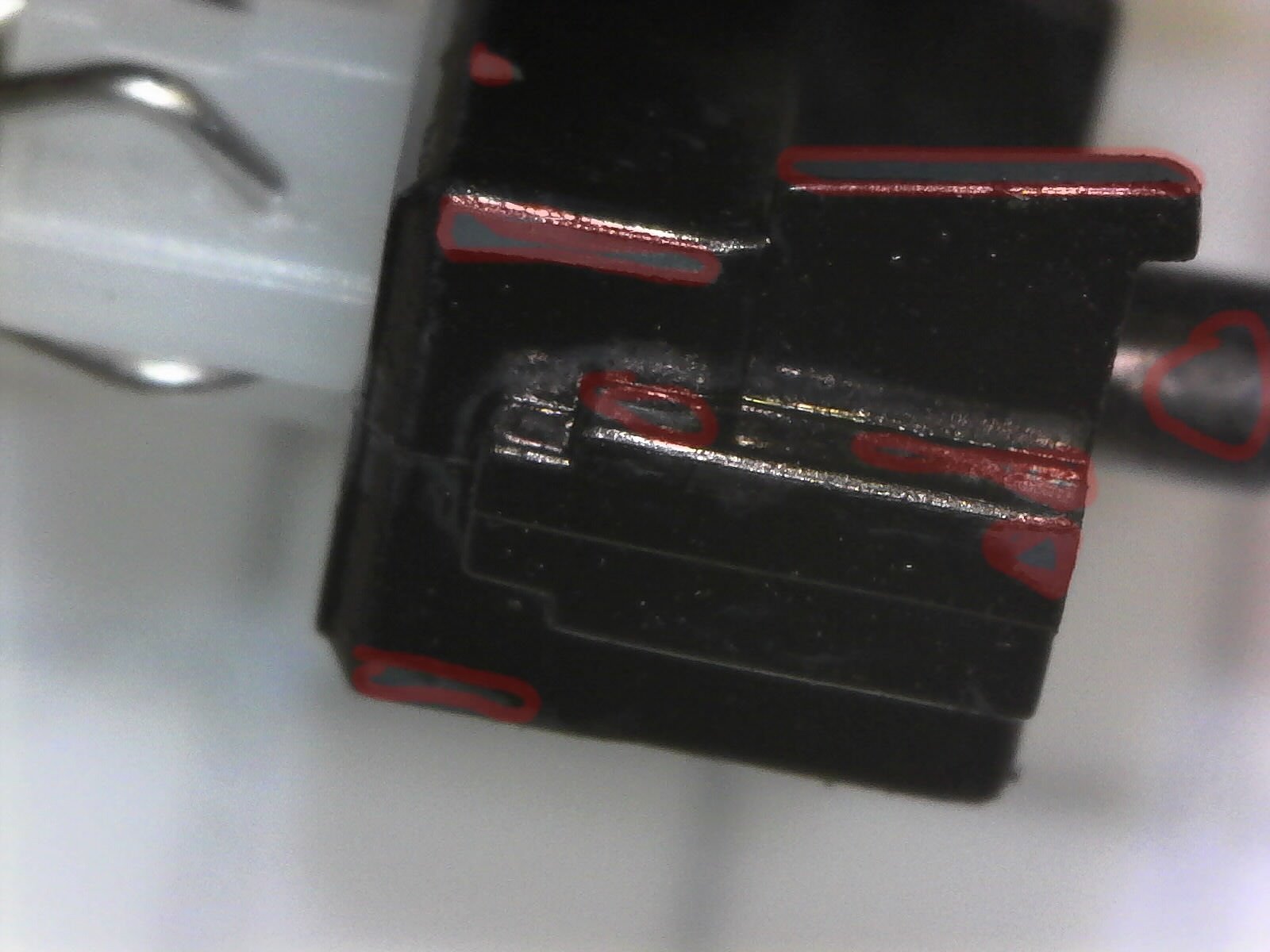

What about the switch tops? The stem rubs against them too, in fact sometimes it rubs against them pretty hard, especially if you hit the edge of the key. If you want maximum smoothness, you might want to consider lubing your switch tops. You can see in this shot that the stem rubbed against the upper wall of the inside of the switch top opening and stained it.

This shot shows that the stem also rubs against the side rails of the opening of the switch top.

This shot shows that the stem also rubs against the lower inner wall of the switch top opening.

Another shot showing just how much the stem rubs against the switch top rails. You should probably either lube this area or make sure the part of the stem that rubs here has enough lube on it that it can transfer the lube to this part of the switch top. Same goes for all of the areas of the housing that show signs of friction.

Another shot showing friction of the stem against the leaf, the rails, and inside of the spring guide tube.

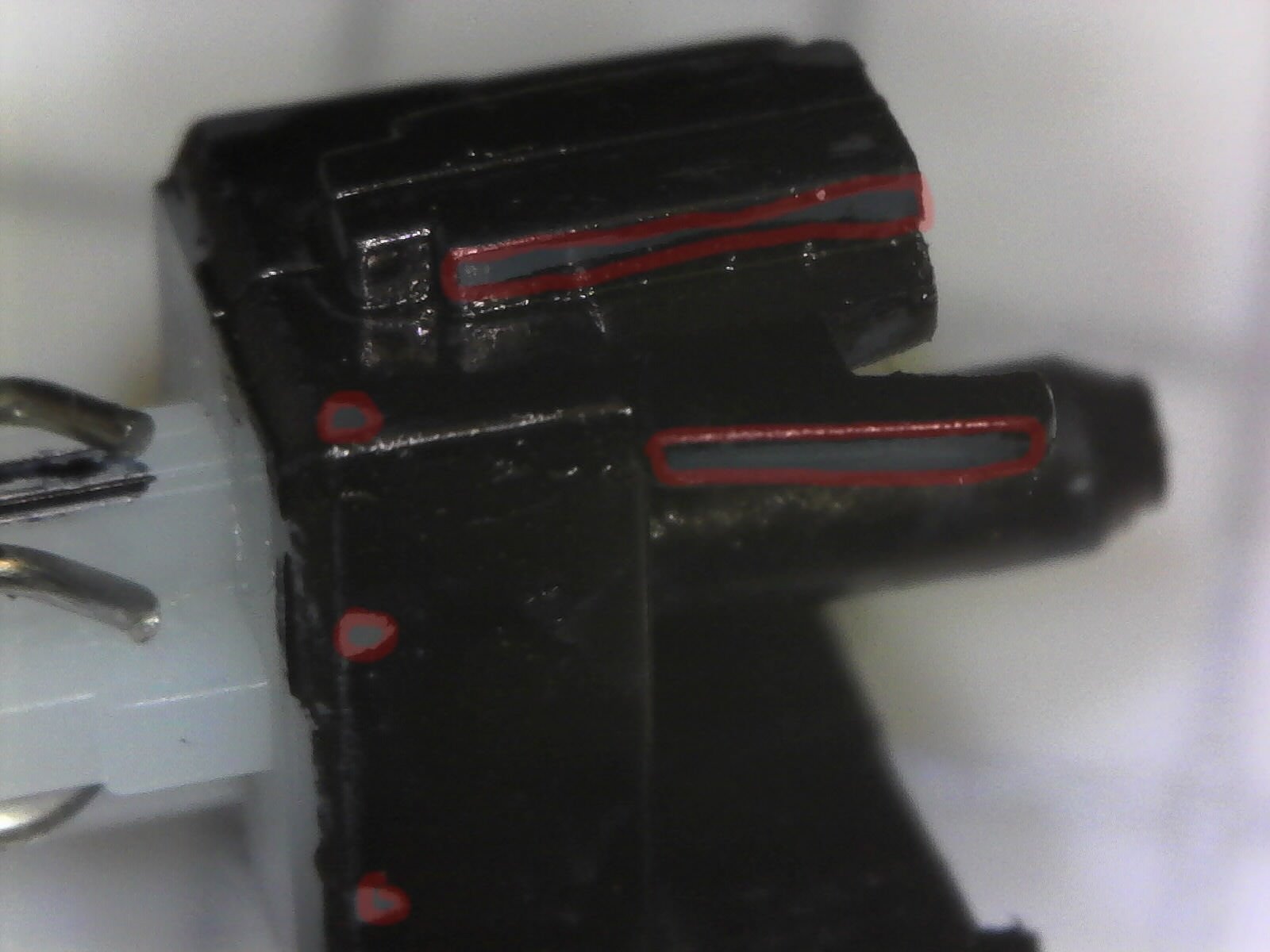

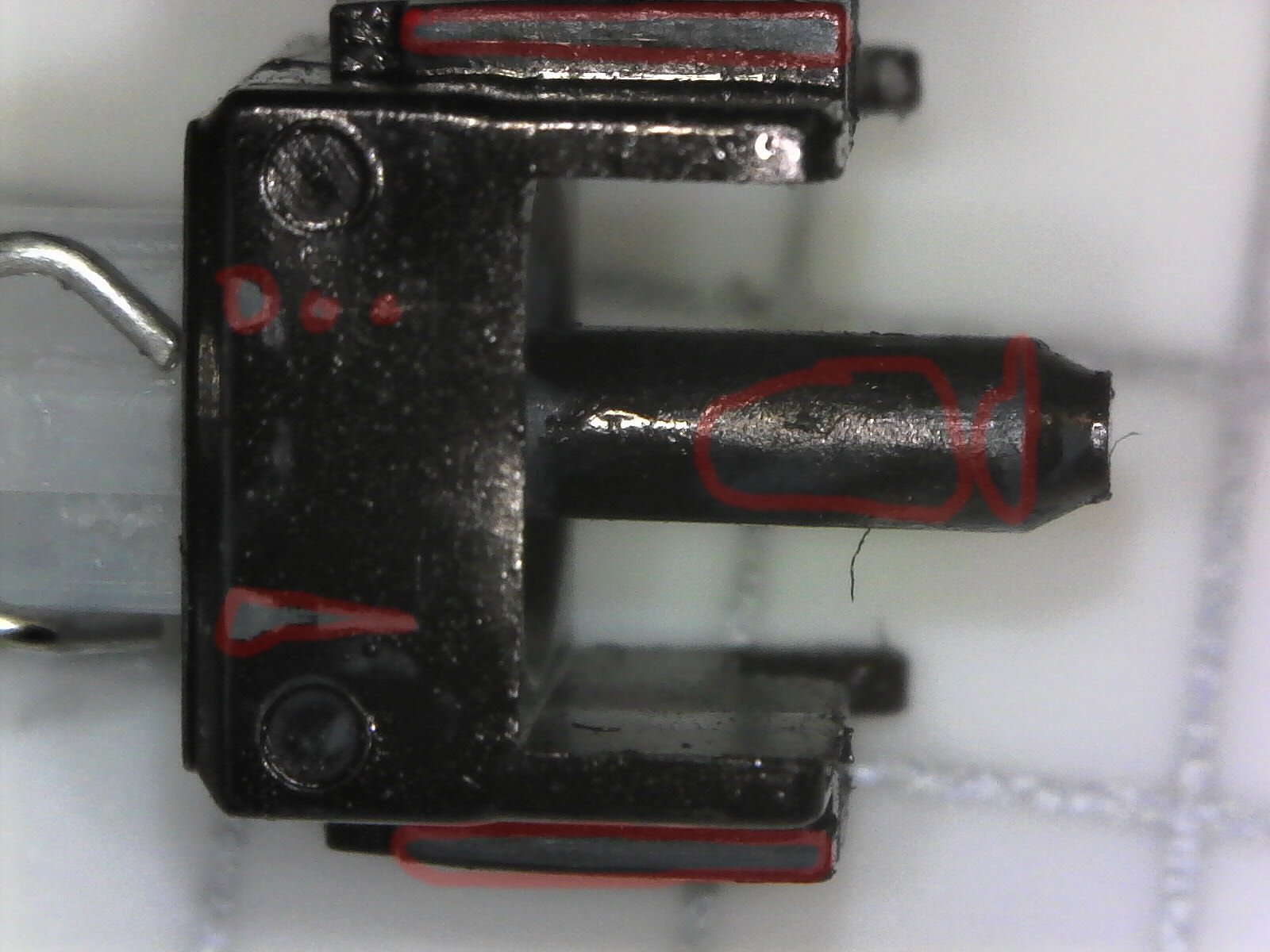

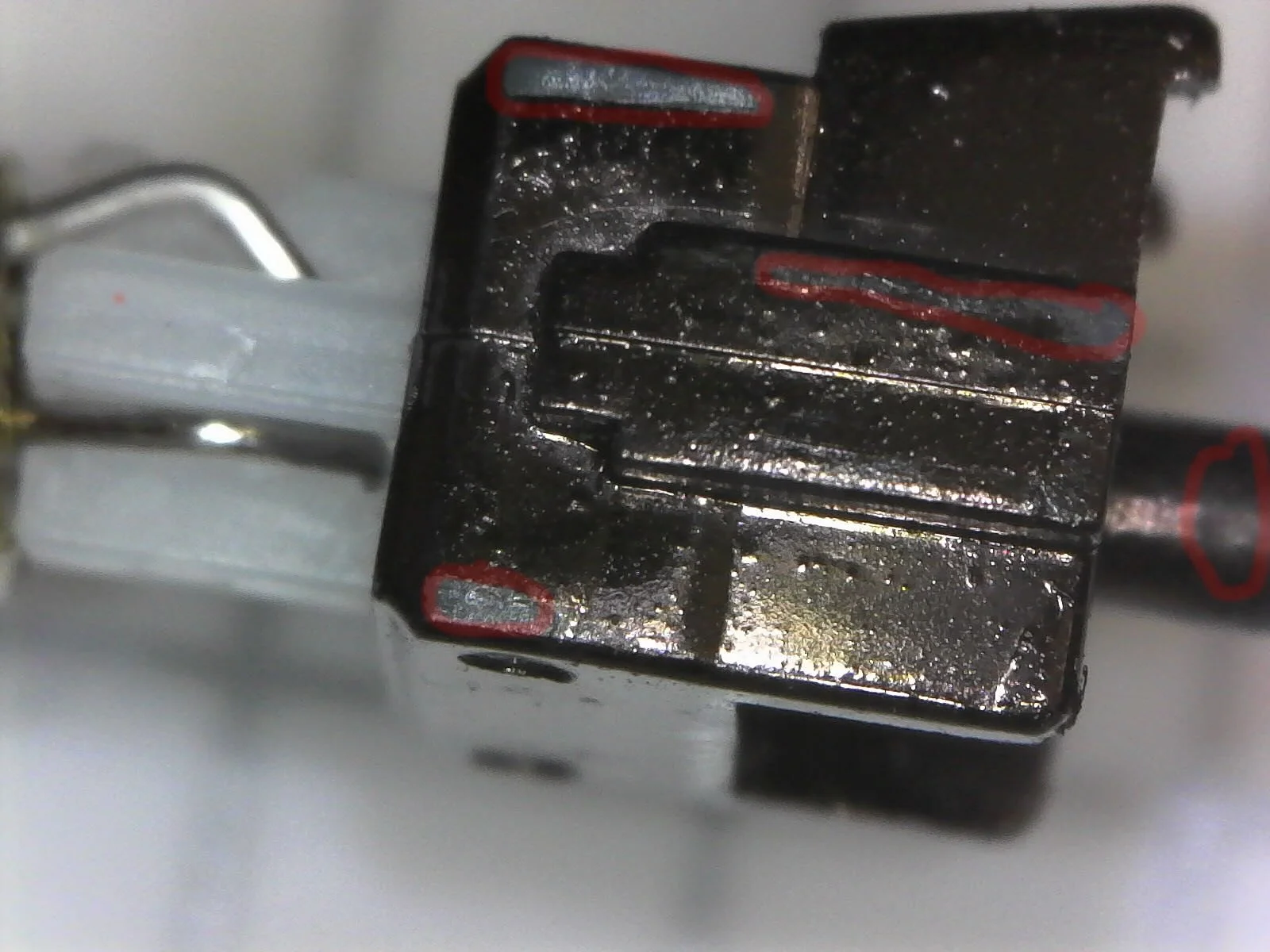

If we look at the stem, we can see what areas had the most friction by looking at where the marker rubbed off of the stem the most. I have circled the high-friction areas in red.

High-friction areas of the stem circled in red.

High-friction areas of the stem circled in red.

High-friction areas of the stem circled in red.

High-friction areas of the stem circled in red.

High-friction areas of the stem circled in red.

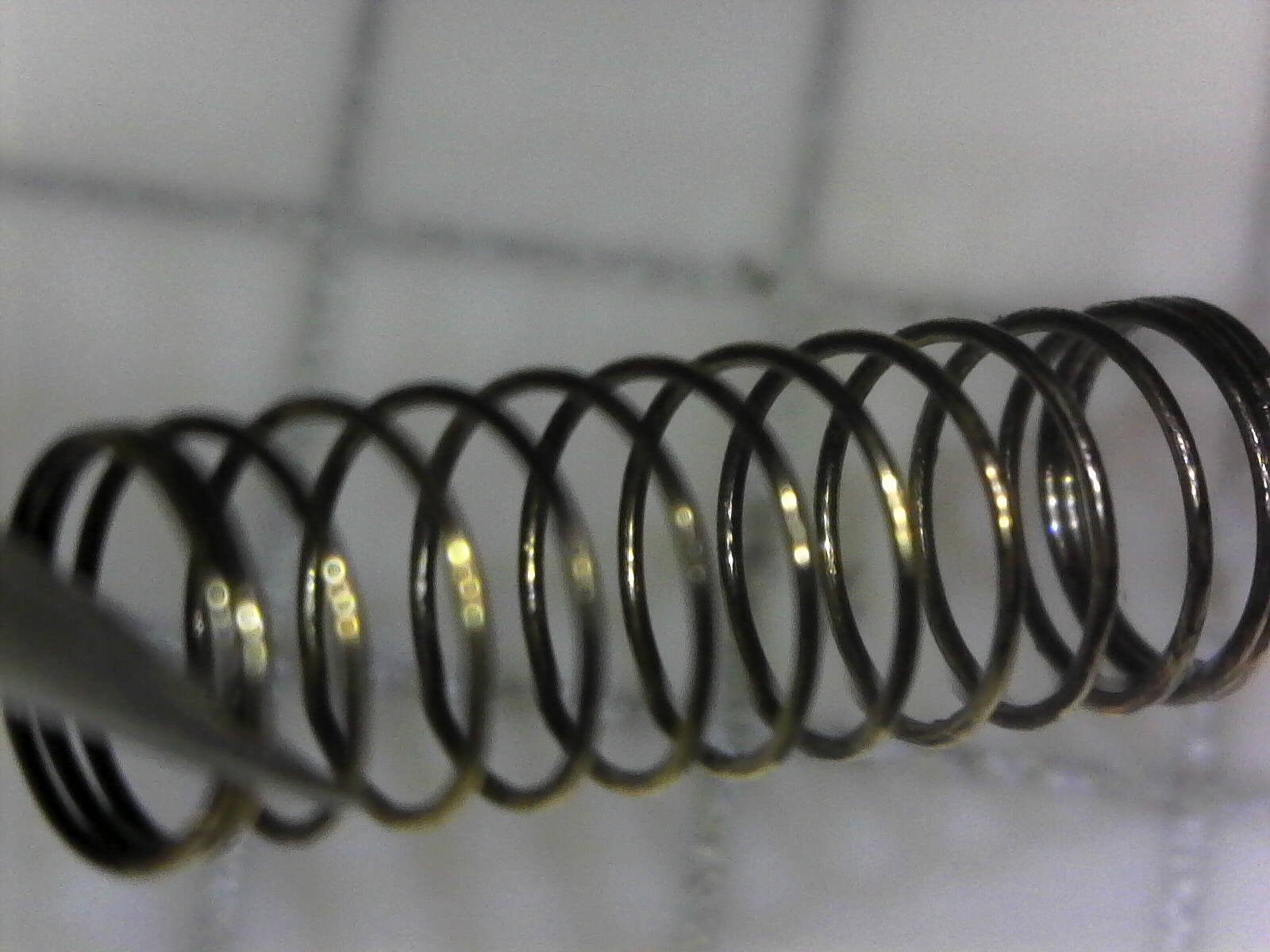

What about the spring? I know from experience that lubing the spring and the areas of the stem and housing that the spring touches make the spring quieter. I tried the same test by applying marker all over the spring, mostly on the ends and on the inside of the coils. Please note that these results might not apply the same to all springs; these are GOOD springs (gold-plated Revo White springs). Bad springs whose coil diameter is too large or too small, or springs with other flaws might have more friction than these. Personally, I would just lube your springs to be safe, but I tried this test anyway.

View of the backside of the stem where the spring touches. I don't see any sign of the end of the spring rubbing hard against this area. I'm not sure this test is very useful though for two reasons: It's hard to get enough ink to stay on the spring to be easily transferable, and I don't think there is as much pressure on the spring as it rubs against the housing and stem compared to the other parts of the switch we looked at. Long story short, I think lubing the spring will mainly make it quiter; you probably won't FEEL a difference, you'll HEAR the difference.

Again, where the spring touches, this time on the bottom of the housing. I don't see ink rubbed off here either.

I see some slight marks of ink on the outside of the spring guide tube. There might be some VERY minor friction here. I would go ahead and lube the outside of the spring guide tube to be safe, but it's probably going to only improve the spring sound, not necessarily the feel of the switch.

CONCLUSION:

For best results with linear switches, you should consider lubing:

- Leaf bumps

- Switch housing side rails

- The inside of the spring guide tube (a THIN coat only, or you will get "lube farts")

- The rails on the inside of the switch top opening - Every surface of the stem

For tactile switches I would consider lubing:

- Switch housing side rails

- The inside of the spring guide tube (a THIN coat only, or you will get "lube farts")

- The rails on the inside of the switch top opening

- Every surface of the stem except for the legs that rub against the leaf

In addition to those areas:

- You can leave the leaf bumps unlubed for maximum tactility

- You would also leave the stem legs unlubed for maximum tacility

- If the switch is highly-tactile and you're willing to lose a bit of tactility in favor of smoothness, you can lube the leaf bumps and the stem legs

- One compromise you can make between tactility and smoothness is to use a thinner lube such as an oil and carefully apply only a light coat to the leaf bump and the stem legs

If you don't want to lube any of these areas of the housing, you should make sure to adequately lube all of the surfaces of the stem that touch those areas so that the stem can transfer some lube to the housing friction areas when it rubs against them. It is possible though that you could end up with dry spots on part of the stem travel though.

Additionally, to improve spring sound, I would also lube the backside of the stem where the spring pushes against it, the bottom of the switch housing where the spring rests, and the outside of the housing's spring guide tube. Alternately, you could just coat the tips of the spring and the inside of the spring coils in lube, or coat the entire spring (what I do). I think lubing these areas or the entire spring is worth doing because in my experience it makes the springs quieter.